-

Notifications

You must be signed in to change notification settings - Fork 52

New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

Error in OLED initialization code #16

Comments

|

Interesting finding. I experienced many display issues before updating the firmware via this repo. But, I still have display issues after 20h printing. Therefore, I will try to measure PWM frequency of the motor drivers and stay away from the harmonics for the clock+divider setting. adding the relevant datasheet informations from p.43 here: 10.1.16 Set Display Clock Divide Ratio/ Oscillator Frequency (D5h) |

|

Jan pointed out, that 187.5kHz might be the PWM frequency. Therefore, staying away from 375kHz would be a good idea to get stable communicaiton but the default setting is hitting the first straight harmonic (380kHz +/-). |

|

Hi and sorry to ask this silly quesiton, but is there a description in how to connect the S42B to the computer? I not an expert in programming microcontrollers, but stumbled across the problem you described on two fo my three controll boards I just recieved recently. I will try the 0x80 default setting and everything is already compiled, so I just need the description on the "hardware part" of how to connect the controller...Thks in Advance |

|

sure, no problem @caesar1111 . It might be better to change the OLED to something 25% faster or slower than 0x80 as this is hitting the PWM frequency as a possible source for interference. |

|

@Quas7 thks a lot, I just order this programmer: https://www.amazon.de/gp/product/B086TWZNMM/ref=ox_sc_act_title_1?smid=A1X7QLRQH87QA3&psc=1 |

|

The programmer looks good and even supports the original ST flashing software (not all clones do that). If you power the board from another source, I recommend not to connect 3.3v (in theory, the stronger voltage source kills the weaker one or just generates heat). I would try the lowest frequency range first with 0x00 (280kHz +/-). This whould be centered somewhere between the harmonics of the PWM. I run S42b only on my extruders as it keeps the motor very cool compared to just pushing current through it with open-loop stepper drivers. For other drivers I did not see the benefit - if I miss steps, there is something else wrong. And even with S42b the timing will get a hit as the central processing unit still does not know that there was a deviation so there will always be a small artefact in the print. On top, I do not need travel moves beyond 500mm/s and for print moves the hotend is still the speed limiting factor in my setups (did not yet try volcanos though). |

|

Interesting discussion. I too can't stand the instability of the OLED screens. They simply aren't useful. I have found that when my printer is powered down and I have the OLED powered through an ST-link or UART, they are super stable. No issues at all. I actually do have these motors on my y and x axis. I like to do a lot of stripes in my TPU prints, so I'm changing colors a lot. I'm a bit heavy handed and sometimes bump the print head when I am changing colors. Print is over right then and there. Also, I recently got a delta printer. Love it. Changing colors on it is a nightmare. I have about a 50% chance of knocking the print head out of alignment. I also like to print fast. Sometimes this causes the print head to come out of alignment. Anyways, I'm hoping these motors fix the problem. I'm not a programmer and most of the programming vocabulary goes right over my head. I am curious though if you all are having success changing the firmware for S42B. I was able to find something online that showed me how to make VScode/platformio compile as a hex file. I use ST utility to upload the firmware to PCB, but nothing ever seems to change. First of all, the firmware I compile is 85KB while the stock is only 73KB. That seems odd considering I've only been changing the PID values. Secondly, when I use the ST utility to compare the stock firmware to a firmware I've compiled, it is wildly different. Doesn't make much sense to me if I'm only changing a couple of numbers. The only way I've been able to successfully change the PID values is through the UART connection and using BTT's serial port assistant. That works, but that doesn't have all the options that you all are talking about with the OLED screen issues. Also, while I'm thinking about it, if I change the PID values in the firmware, compile and upload, then check them through the UART connection and BTT's serial port assistant, the PID values are still the same as they were before. It's weird. Nothing changes when I compile a new firmware. |

|

Just thinking, maybe it is easier to enable "advanced pause" in Marlin and do a home-after-change? I have also bought last week an ultra cheap delta printer (FLSUN Q5) and I love it as it is really ultrasilent after a few mods (fans, hotend, UART steppers, BMG extruders, etc.) but as it is a bowden I do not touch the print head for changing filaments at all and I installed a TL Y-splitter for automatic 2 color prints. Regarding your flashing issue. My binary compiled via vs code + platform.io is located in \firmware\S42BV1.0.pioenvs\BIGTREE_S42B_V1_0\firwmare.bin And second thing... you do change these initial values in main.c, right? and it seems, that for the MKS servo42b (very similar product) there are units sold with a controller protection. |

I just got that one, or one just like it - and am having really mixed luck with it. Some times it'll connect, sometimes it drops. I don't trust this controller and I don't trust the STLink and it's been a LOT of debugging. I'm looking forward to seeing how that goes for you. The first time I tried programming it powered by the dongle (and DISconnected from the printer by pulling the white cable) it didn't work, and plugged into printer it didn't work until I fed +5V on the 5V line. Today, it only works powered from the dongle and not when powered from the printer. Perhaps a seperate thread for general programming issues makes sense so as not to clutter firmware issues.

I was using the same process this morning. My firmware was 30,872 bytes, like the one @Quas7 posted. I couldn't get stuff to upload from VSC/PIO but I can't tell with all my connection issues what's going on. I'm getting .bin files, BTW. Are you hand-calculating the checksums? I found a calculator, tried to write a spreadsheet, but I think I'll have to get into VBA or something to get the checksums and was figuring I'd just use the online calculator. :-\ Re: Changing filament: You should be able to do that with just g-code commands, or through the menus, you can set up load and unload procedures where you shouldn't have to tweak the extruder directly, I've got this on both bowden and direct drive units... And even so, I don't knock the head around as long as it's locked in position... Perhaps a Delta would be less stable? Lastly: //Set gain constants here. OEM defaults are 30/10/200 and edited 314-316 to be: I just don't like scrolling. |

|

@AbeFM I can feel your pain with the programmers. For uploading with stlink clones I noramllyy use st-flash: https://github.com/stlink-org/stlink The problem with the S42B is mainly the PWM output stage, if the board is "enabled" (normally it is active low!). |

|

Quas7 - Funny. I just got the FLSUN QQS. Changed out the board for an SKR 1.4 turbo with 2209s. Loud as can be. Easily my loudest printer and my corexy and cartesian also used to run the same setup and you could barely hear them. I have to learn more mechanically about the delta to see what is causing all the racket. But man, do I ever love the speed of the delta. I've always used Cura as my slicer. Works good enough for me. I just use its function to pause at a certain layer and move the head away from my print. I manually pull the filament out and change it. I don't touch the print head at all for my delta to do this (bowden setup), but the print head slightly moves almost every time no matter how careful I am. This is what originally got me on the idea of these closed loop setups. I like your idea of advanced pause feature, but I'm afraid I would still run into the same issue. Also realize I'm doing this with TPU. Sometimes I have to push hard to get the new filament pushed into the hotend. It's uncommon for me to bump my CoreXY or cartesian, but it still happens (probably 10-15%). I've already noticed that the closed loop function still works when my printer is paused. I've pushed hard on my print heads for both of those printers and it snaps back into place - waiting patiently for me to change the filament. :) This is obviously a "me" issue. I'm heavy handed and I'm just looking for an extra "crutch" to help me out on these filament changes. Especially once I convert my delta. I changed something in VS code or something in platformio.... I can't remember. Somehow, I got it to compile into a hex file. I thought I had to do this because the S42B firmware is hex. I didn't know I could compile it as a binary and just use it that way. That would be a lot easier. Yes. I check the timestamps on my files. lol. That's one of the first things I learned when I first downloaded this software to compile marlin. Learned that the hard way. I'm definitely uploading my latest compiled hex files, but now I'm super curious to try out using binary to see if that works. I'm tired of doing all the checksum calculations using BTT's serial port assistant. Yes, the lines you mentioned in the firmware (314-316) - those are the ones I've been changing with no luck. Nothing happens. We'll see when I try with making a binary file. AbeFM Yes, I've been hand calculating the checksums (just learned what that was the other day). I too thought about making a spreadsheet, but things get more complicated, at least for me and the time I want to spend, when it comes to adding up the negative numbers. And that one took me awhile to figure out (especially the D value if you want to try something above 255). You have to use the negative value (didn't know that was a thing when I first looked at this) for A2 (A0 or A1 for P and I), then add it to 05 and your new value you want to put in for P, I or D. However, it all has to stay in 8 bit form, so the checksum can't be bigger than 2 characters. In that case, you need to split up your new P, I or D value into 8 bit form and add those two numbers separately. Took me way too long to realize that one. I have a feeling though I'm just saying things you all already know. Hexidecimal is all new to me. The thing you did with setting the gain constants, do I have to do that to change them? I tend to just leave my VScode open to the spot where I want to change. Really no scrolling involved. Yeah, I figured I could use gcodes to do a color change, but I found a way that works for me. Every time I've tried to setup something via gcode, something goes wrong. Like after a color change the print head will go back to printing but push out another 50mm of plastic first before restarting and thus ruin my print. I could keep trying to go down this route, but I like what I do. For the most part, it is easy. I could try sending the printhead to home to change my filament, but its extremely hard for me to do on my corexy at the home position. The cartesian would be easier, but I guarantee I can still bump it out of place. Most of my color changes go smoothly. Sometimes things just get stuck and I have to force it a bit more to get through the extruder (Hemera on my corexy and bmg on my delta and cartesian). That's usually when I bump it. As for the delta, No matter what, I'm going to bump it. Doesn't matter where I tell it to home. |

|

@nhabes79 And I just noticed, that all this checksum magic is maybe needed because the devs have been aware, that there is an EMI issue for an enabled drive stage. ;) And regarding the homing thing. The trick would be to home after changing the filament. No matter how hard you bumped it during filament change, it would just resync the coordinates and know where to start printing again. I think, that is one of the advanced pause features of marlin that can be enabled (home after pause or something like that). |

|

In case, you want to temporarely convert your cheap stlink v2 clones to a blackmagic probe: https://github.com/sakana280/stlink-tool |

|

No problem @nhabes79. Obviously, you do not need a blackmagic probe or anything fency as your clone is working with the ST link software (many stlink v2 clones do not work this way). I think, the flashing you do is actually not erasing the part where these values are stored. |

|

@caesar1111 are you sure, that this is really XY is overshooting and this is not just overextrusion because of low Jerk/Acceleration at corners? Did you try with "open loop" (switch 3), if you get the same? |

|

@Quas7 its a good point. I didnt have the issue when I was running the printer with 0.9 steppers and TMC2209 for X and Y... but I was also changing to Volcano hotend in the process of migrating. |

|

Ok, with a volcano this non-linear effect is even more pronounced. |

Ok, I have to laugh, but that's exactly what I did that has completely messed up my S42B board (full chip erase, then flash with stock ITEM.hex firmware). No idea why. I have some new S42B boards coming in, just a shame I can't adjust this particular one anymore. Everything else on it still works. It still runs the motor fine in my printer, I just can't adjust the PID values now. |

|

@nhabes79 All flags shood look like in this screenshot (readout from a S42B): Especially the WDG_SW has to be enabled, otherwise it will reboot continously. |

|

To get back to the orignal topic and close this. I do not see any more display glitches and I do not notice any other issues with this. 0d80 = 0b 0101 0000 = ~320 kHz clock and divider 1 I will therefore start a PR for others to test this as well. |

Oh, Ah! I didn't know this end could negotiate for slower speeds - totally I'll do that, the 4MHz would rarely, rarely work.

And there's a good chance this is at the heart of my rebooting continuously issue. My flags were all messed up, I'll take another look. Pretty cool about the screen timing. Hasn't been an issue here, but it's a good approach. |

|

@Quas7 Regarding the PWM frequency, I hooked up my scope to the VRef pins of each driver and tested it. It was indeed very close to 187kHz so I can confirm it. Wasn't spot on but could be because the MCU uses the internal clock... |

|

...ok, the OLED shut down on its own after about 8hrs.... but way better than the 30 sec. before flashing. |

|

@Quas7 will test this also.... right now I am running PID at around P70I10D70..... strange but this is closed to the open loop print where I have no overshoot.... |

hmm, I think enabling the OLED updates also during idle would not be complicated. But 10sec are really too fast to go for the re-init idea. I use the display only for the menu but now I figured that I did not even test, if the menu items get reloaded without pushing any button. ;) |

|

@Quas7 ...ok here we go with the first test results with the OLED plugged in directly running the TrueStep firmware:

|

|

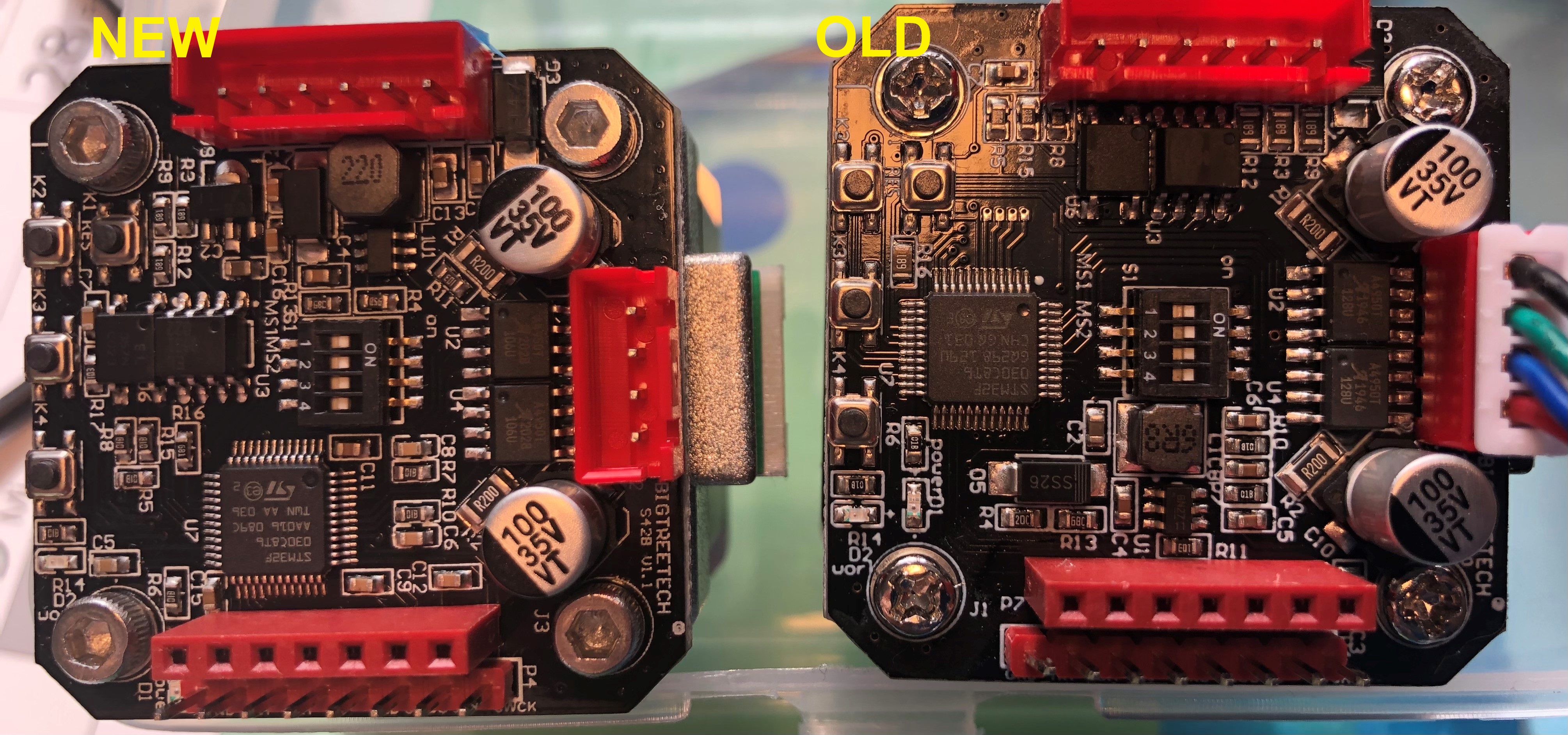

@caesar1111 alright. One last shot... could you post a picture of the boards especially the STM32 controller? This behaves so erratic that I almost suspect counterfeit stm32 hardware that is very common on bluepill dev boards etc |

|

|

|

here one of my boards for comparison. What I see in a quick comparison:

at least the STM32 does not look like an obvious fake part @caesar1111 |

|

@swanepoeljan thanks! I had no chance to identify this 6pin DC/DC converter without nowing that only "BN" was the identfier. ;) |

|

...it really looks like a mix and match thing they do with the components... I can see that no board of ours is alike. Diodes, inductors and ICs are not matching up. I will have a closer look on my other 4 boards and see if I have at least some consistency there… |

|

@Quas7 and @swanepoeljan : |

|

Not sure, if this is a real indicator as ST has multiple packaging and test facilities so there should not be much difference in the controller, if they are genuine. I would also expect especially during the covid supply chain crysis that some components got 2nd sourced as well. I still suspect the board layout with the buck converter close to the com header is giving the main issue depending component tolerances. |

|

found our guy (via aliexpress "BNOG" search...): https://datasheet.octopart.com/AOZ1282CI-Alpha-%26-Omega-Semiconductor-datasheet-67314984.pdf It runs the PWM on 450kHz +/-90kHz as we measured. That range might explain, why different countermeasures work on different boards. BTW, 220 on the inductance does not mean 220uH it is 22uH. Which also fits perfectly the firs page datasheet example: And the table fits the selected components... The 68C is a 49.9k and the 20C is 15.8kOhm I already know from the BTT SKR boards that they really like to use the datasheet examples as best practise. |

Great found! You have a gift for sniffing these kind of things out! ;) |

This is interesting and worth testing out. Maybe polarity of inductor matters noise-wise. I am looking into theory behind this.

I believe we are trying to avoid saturation of the core. Even datasheet states saturation is not desired. Larger inductor is easyer to saturate, this might be why larger inductor (22uH) seems to perform worse than 6.8uH, but it is weird since board shouldn't draw THAT much current really. Still worth looking into issue. Inductor package seems to be NR4018, quick search on mouser: https://eu.mouser.com/_/?keyword=NR4018 I will try to do some calculations according to datasheet of the chip. Just slaping capacitors on board isn't really necesarily solution... From my calculations both inductor should work fine with DC/DC chip, but note that measurements in datasheets are made at 100kHz going above that frequency does black magic. |

I would be very supprised if there is any polarity dependence or more precise winding orientation dependence that would matter for sub GHz noise figures. Not even save to assume that the marking is giving any orientation at all for the winding direction. ;) Note, that 6R8 is one worst and one best board in our collection. My 220 boards are average with hours of flawless operation.

Correct, saturation is bad. And provoking failures is the key of debugging that is why one would overload or saturate the core here on purpose to find margins for a coarse tolerance calculation. And clearly, for same form factor or same core geometry more windings saturate the core more easily. The inductor and diode current peaks are also much higher than the average dc current provided at Vout.

For bad board designs adding caps piggyback is normally the best you can do. ;P |

|

These are great findings! These seem to me like typical buck converter switching noise case (or perhaps ground line problems, but this will be much harder to diagnose or fix).

That again indicates the problem is with switching transients. I think it would benefit smaller low ESR/ESL ceramic capacitors, 10uF THT is just not going to help much in my opinion. Also there is more than enough capacitance from two big electrolitics, 10uF just wont do anything.

Again I would suggest going for smaller capacitance with low ESR, 10nF? I believe good idea would be to measure actual value of C2 since that is pretty much only real output capacitance. If it is small 100nF-ish capacitor, then we do need to add about 10uF, maybe even better 4.7uF tantalum - KEEP ESR/ESL LOW! If C2 is one of those high capacity tiny capacitor (1-10uF ceramic tiny thing), which I doubt since they seem a bit expensive for putting on chinese mass produced cheap driver, then ESR/ESL is over the roof, then adding small 10nF-ish capacitor in paralel should help. I did try random electrolitic capacitor I had laying around on OLED 3v3 pins, but of course, it is far away from source of noise and ESR values are not great, so it did not help at all.

I don't believe it is anything STM operated, since removing all the functionality and code except OLED did not help the issues with OLED. A4950 do use fixed off time of typical 25us but, datasheet does state minimum and maximum times of 16us and 34uS. It should not do much when motors are of though. Might even be some timing thing inside OLED module.

That will probably eliminate problems, and it probably would be most reliable solution to just throw linear regulator on instead of switching regulator. That is however a bit... hard to expect everyone to modify their boards to that extent. I will try to find some components and experiment with adding capacitors where I believe they are needed. |

|

I would habe piggy packed 0806 but had no 10uF available.

what do you mean with "expensive"? Those 0806 kemet with 10uF are all <1cent parts in 10kpcs, if one does not need high voltage ratings. It is still a factor of 10 above a 100nF kemet but not expensive in my opinion. As can be seen above, a ultra high-ESL THT 10uF kerko already solves the issue with +33mA overloading. Solution for non-solder guys is hopefully buying v2. ;) |

|

I hope V2 are better... unfortunately I do not have money to buy a set of V2 drivers so I am stuck with what I have. Thankfully I am very solder guy :D so I will have to do with what I have. Shall I do some tracing back of connections maybe? it would be painfull job probably. Can we identify cap that is on the board currently? Maybe measure it in circuit? and complement it with correct complementary capacitor? I should head to the basement on some further research on circuit board topology. I will try some stuff, but I only have recycled parts at the moment since our country is in a lockdown. EDIT: IDK WHAT I DID SUDDENLY ONE OF MY DRIVERS IS STABLE?!?! |

|

@kablek there are not too many connections or components for the 3V3 so tracing should be job of 10 minutes, I hope. But all information is welcome, of course. :) And the STM32 is capable to sink 120mA depending on pin switching. It is by far the biggest customer on the 3V3 rail and I did not yet beep out, if they added the datasheet advised 2x100nf+ 1x4.7uF to its VDDs. I tried with a VNA and with my trusty multi to measure in circuit the impedance of the 3V3. No chance as the rail is just to leaky. Guess, you made the same conclusion in your edit above. But, as stated already, BTT loves staying close to the datasheets and it most likely simply a 10uF. Yes, C4 is the boostrapping cap for the NMOS gate driver. My first guess would be, that the magic stability is some kind linked to a temperature effect that comes along with the soldering. Maybe you wait 10 min and retest, if it is getting unstable again and maybe just use a hair dryer as I intended before but just did not yet experimented with as I solved it brute force with 10uF already. ;) |

|

Guys, we don't need to trace with multi meter and probing. Open repository file "Item-Pinmap.PDF" in PDF viewer that supports table of contents toolbar (I use SumatraPDF). Open up TOC, all the nets and pins on those nets are in TOC. And yes C4 is bootstrap capacitor, and C2 is THE ONLY capacitor on 3v3 line! Also note that there are pads for connections with PC14, PC15, PF0 and PF1 on the board. I shall do some more investigation here :D EDIT: also MOSI and MISO for magnetic encoder are connected together. EDIT 2: There is begining of my reverse engineering altium project in my fork |

|

Similar fix but a bit easier to apply https://youtu.be/6yggQ2xOTqc |

|

@Quas7 so what capacitor you are suggesting? I will just solder it to the jumper wires for testing, since I am planning to to an angeled bracket for my display anyway.... nad I am waiting on some feedback from the printer facebook page for the PID setting using the S42B on a Z axis..... |

|

normally, one would need 1x 4.7uF "global" +4x 100nF per pin of the STM32. Therefore, with short leads a 10uF ceramic would be my first guess also for the pin header although @kablek had less success with that but he had only an electroylitc capacitor at hand that is not well suited to filter high frequency noise that we see here. |

|

...finally. While installing the steppers on a new printer, I had to undergo the PID tuning again and found out that there is a new version of the https://github.com/swanepoeljan/TrueStep out there. Great job on that, makes using the S42B much easier. |

In the file oled.c, where the clock divide ration and oscillator frequency are initialized with the 0xD5 command. The parameter

in the file is "80", but I think it should be the hex value "0x80". This might address some of the display instability issues.

The text was updated successfully, but these errors were encountered: